Raw natural gas is composed of several gases. The main component is methane. Other components include ethane, propane, butane, and many other combustible hydrocarbons. Raw natural gas may also contain water vapor, hydrogen sulfide, carbon dioxide, nitrogen, and helium.

During processing, many of these components may be removed. Some such as ethane, propane and butane are completely removed processed and transported by TPDC loading ships. Other components such as water vapor and carbon dioxide are removed to improve the quality of the natural gas so as to make it easier to move the gas over great distances through pipelines.

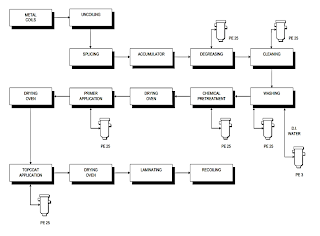

The manufacturing process:

The methods used to extract, process, transport, store, and distribute natural gas depend on the location and composition of the raw gas and the location and application of the gas by the end users . Here is the flow sheet of typical natural gas plant.