Rice flour production process

Black and green tea processing

Learn how to read piping and Instrumentation Diagrams:

Series: Part one «

Series: Part two «

Series: Part three«

Series: part four «

Series: Part five«

Mono Ethylene Glycol(MEG) regeneration process flow sheet

Natural gas processing with flow chart

The methods used to extract, process, transport, store, and distribute natural gas depend on the location and composition of the raw gas and the location and application of the gas by the end users . Here is the flow sheet of typical natural gas plant.

Amine gas treatment process with flow sheet

Amine treating plants remove CO2 (carbon dioxide) and H2S (hydrogen sulfide) from natural gas.

Flow sheet of Amine treatment ( drawn by RFF software)

Download the software flow sheet software

Amine Gas Sweetening Process

- Sour gas enters the contactor tower and rises through the descending amine.

- Purified gas flows from the top of the tower.

Pharmaceutical formulation process

Petrochemical chain-Phenol Production

How to make excercise books

Alkyd Resin production process Updated

Gem stone production process

How to make egg tray from waste paper

Sulfuric acid production process flow sheet

The catalytic reaction generates a lot of heat and is reversible. The catalyst tower is, therefore, arranged with

Corn flakes production process

The flakes are then tumble toasted in huge cylindrical ovens. The air in the ovens is heated by 600C0

Surgical Dressing making process

Basically the production process involves manufacturing of cotton fabrics by knitting and then producing of swabs from the knit material. The detail presentation of the process is presented as follows:

Confectionery production process

Toilet paper production process

Spices production process (dry grinding)

The process of dry grinding is very simple which starts from the procurement of whole spices sent to the grinding process where mixing is also carried out. Mixed spices are stored in tanks or large sized tumblers from where it is shifted to the packaging machines to be converted into desired packet sizes.

Gabion - mesh wire - making process

High purity polycarbonate production process flow sheet

More on polycarbonate production process

http://www.icis.com/v2/chemicals/9076147/polycarbonate/process.html

Top 10 tips on polycarbonate processing

http://www.plasticsmachining.com/magazine/2001-11/pp-poly.html

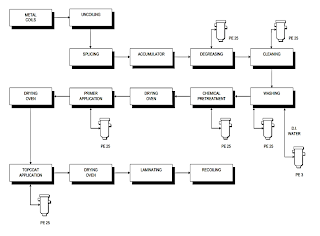

Electrocoating paint processing flow sheet

More http://www.electrocoat.org/guide/consumers.html

Electrocoating http://www.p2sustainabilitylibrary.mil/p2_opportunity_handbook/1_9.html

Edible oil refinery process flow sheet

Floor Coverings and mat of VULCANIZED RUBBER

Introduction

Floor coverings and mat of vulcanized rubber are flat colored and patterned piece of material used to cover floors of houses and automobiles. Since they are washable with water and durable in comparison to other type of floor coverings, they are widely utilized for covering the floors of automobiles.

Raw materials

The major raw & auxiliary materials for the production of floor covering and mat of vulcanized rubber are natural and synthetic rubber, carbon black, process oil, whitening powder, zinc oxide, stearic acid, anti oxidant, normal sulfur and accelerator.

Process Production

The manufacturing process of floor coverings and mat of vulcanized rubber can be broadly be classified into three stages, mixing, building and vulcanizing process.

Rubber is mixed with other ingredients

Vodka production process

Silk Yarn Production Process

Raw materials

The main materials are silk fiber, Spools, cops, reels and cons.

Production Process

Hatching of eggs

Sericulture, or the raising of silkworms, involves the incubation of the tiny eggs of the silk worm moth until they hatch and becomes worms. After hatching, the worms are placed under a layer of gauze, on which is spread a layer of finely chopped mulberry leaves. For six weeks, the worms eat almost continuously. At the end of this period, they are ready to spin their cocoons, and branches of trees or shrubs are placed in their rearing houses.

Silk Production

The worms climb these branches and make their cocoons in one continuous thread, taking about eight days for the process. The amount of usable silk

Recycled plastics making process

Mechanical recycling

Polyester Production Process

High purity polycarbonate production process flow sheet

Epoxy resin manufacturing process with flow chart

Plastic Buttons Making Process

Soft drinks production process flow chart

Sugar is delivered either in hopper cars with pneumatic discharge or in bags. For reasons of micro-biological stabilization, the sugar syrup is produced in a hot dissolving process. The sugar is admixed by

Paper tubes, spools and drums making process

Paper tubes or cones, spools and drums are widely used as packages, shipping containers and component parts. These products are commonly used in the textile factories for winding threads and yarns as well as to form rolls of woven cloth or fabric (which in the later case the paper tubes are usually called bobbins). Also paper tubes are needed in plastic factories that produce poly films, sheets and woven fabrics. Paper factories as well require paper tubes for winding products such as toilet tissues and related items.

Kraft paper reel is unwounded and punched out into fan shape for paper cones and rectangular shape for paper tubes. After beveling and

Rubber threads and chords making process

Rubber threads and chords are primarily used to manufacture various types of elastic tapes mainly for foundation garments like briefs, trunks and panties. They are also used in elastic types for shorts, skirts, sportswear, sock tops, shoe uppers, head bands and wrist bands for sportsmen and travel goods.

The raw and auxiliary materials of the project are natural rubber latex (60%), potassium oleate,

shawl, veil and mantilla making

A shawl is a simple item of clothing, loosely worn over the shoulders, upper body and arms, sometimes also over the head. It is usually a rectangular or square piece of cloth, often folded to make a triangle, but can also be triangular in shape at the beginning. Other shapes include oblong shawls.

Shawls are used in order to keep warm, to complement a costume, and for symbolic reasons. Today, shawls are worn for added warmth (and fashion) at outdoor or indoor evening affairs where the temperature is warm enough for men in wool suits but for women are dresses and where a jacket might be inappropriate.

A veil is

Cotton and synthetic knitted hose: Production Process

The major raw materials used in the production of cotton and synthetic hose are synthetic and cotton yarn .

The yarn (cotton and synthetic) is purchased directly from the market and wound up on reels in the form of warping beam by winding machine. Then it is placed on a circular knitting machine and the fabric is knitted. |It is then drawn up wards, the wound on a roller. The hoses are finally coiled/spooled by coiling machine, in standard lengths and packed up and dispatch. The only waste of the process is rags which can be used for the production of pillows and mattress as a result the process is environmentally friendly.

Some equipment: a circular loom for weaving hoses Winding machine Coiling machine